In recent years, with the implementation of the national agricultural machinery purchase subsidy policy, the adoption of tractors in rural areas has significantly increased. However, many tractor operators still lack a proper understanding of these machines, leading to frequent breakdowns and higher maintenance costs. These misconceptions in operation mainly fall into the following categories:

First, there is a common attitude of underestimating the complexity of tractors. Some operators believe that tractors are simple machines and not as sensitive or reliable as cars. As a result, they often drive them carelessly on rural roads, where traffic is light and accidents seem less likely. This mindset leads to reckless behaviors such as speeding, overloading, and improper use. Unfortunately, the simplicity of their design doesn’t make them more durable or foolproof. Ignoring proper operation and maintenance increases the risk of serious accidents.

Second, many operators neglect the importance of the break-in period. They may skip this crucial phase after purchasing a new tractor or after major repairs, thinking it’s unnecessary. This leads to premature wear of internal components, reducing the machine’s lifespan and increasing the likelihood of mechanical failures.

Third, improper lubrication is another major issue. Operators often overlook regular oiling schedules or miss critical lubrication points that don’t immediately cause problems. Over time, this can lead to severe damage. For example, failing to refill the oil pan or clean the air filter can result in engine failure or other costly issues.

Fourth, some drivers try to save money by using cheap or substandard parts. Reusing old oil or installing faulty components might seem cost-effective at first, but it often leads to bigger problems down the line. For instance, using contaminated oil in the hydraulic system can cause malfunctions and further damage.

Lastly, fuel and lubricant choices are often made without considering seasonal changes. Many operators use the same type of oil year-round, which can be inefficient and even harmful. In colder months, thick oil can make starting the tractor difficult, while in warmer weather, it may not provide adequate protection. Proper oil selection based on temperature is essential for smooth performance and longevity.

By addressing these misunderstandings, tractor operators can significantly improve safety, reduce repair costs, and extend the life of their equipment.

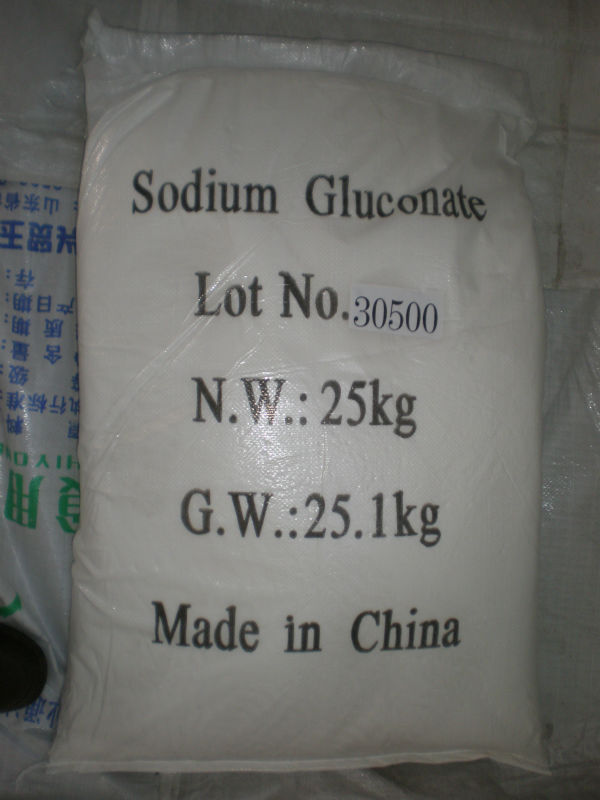

Construction Chemicals

Molecular formula: C6H11O7Na

Molecular weight: 218.14

Properties: white crystalline granule or powder, easy to dissolve in the water

Standard:

Quality standard

Item standard

Industry grade: food grade

Identification in: accordance with standard

Assay: ≥98.0%, 98.0 - 102.0%

Loss on dry: ≤0.50%; ≤0.30%

Reduzate: ≤0.70%; ≤0.50%

pH: 6.2 - 7.8; 6.2 -7.8

Sulfate: ≤0.05%; ≤0.05%

Chloride: ≤0.07; ≤0.07

Pb: ≤2μg/g; ≤1μg/g

Arsenic salt: ≤2μg/g; ≤2μg/g

Heavy metals: ≤10μg/g; ≤10μg/g

Appearance of solution (1.0g, 10ml water): colorless, almost clear

Usage:

1, In the medicine field, it can keep the balance of acid and alkali in the human body, and recover the normal operation of nerve. It can be used in the prevention and cure of syndrome for low sodium. In this purpose, it also can be used as Food Additives

2, It can be used as water quality stabilizer because it has excellent inhibiting capacity to scale

3, Used as surface cleaning agent of metal

4, Used as cleaning agent of glass bottle

5, It also can be used as water reducing agent and retarder in the building industry

Packaging & Shipping

Packing: 25kg in plastic film bag lined plastic woven bag, or following your demand

Sodium Gluconate,Nano Silica,Concrete Retarders Sodium Gluconate,Construction Chemical 99% Sodium Gluconate

Shandong Tiancheng Chemical Co., Ltd. , https://www.tianchengchemical.com